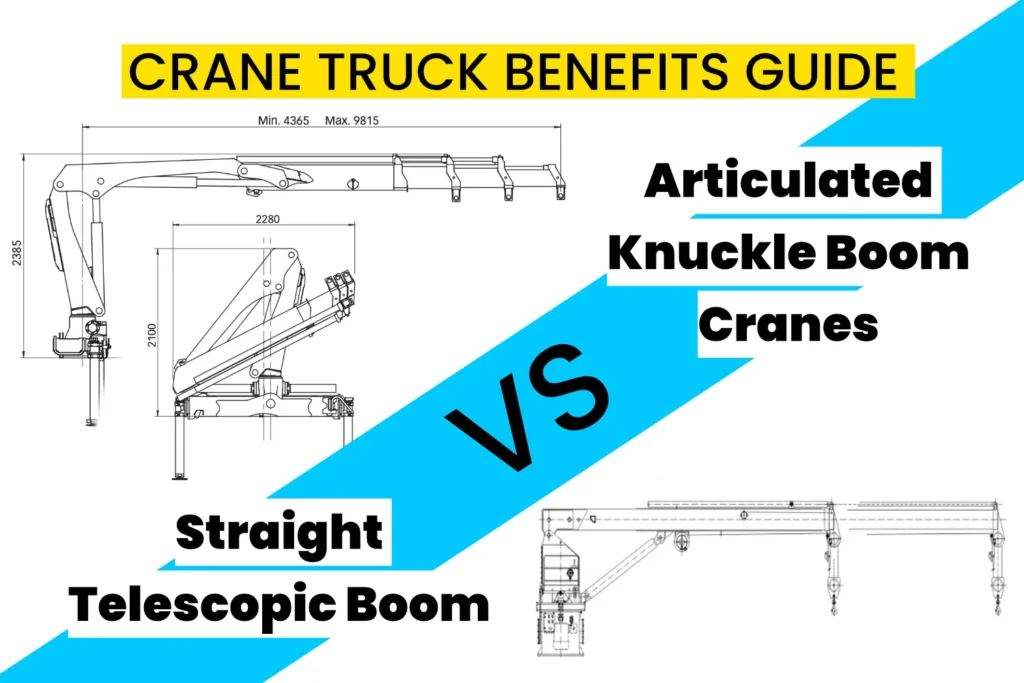

When it comes to moving heavy materials efficiently and safely, crane trucks provide an all-in-one solution that combines transport and lifting capability in a single vehicle. But not all crane trucks are created equal. Understanding the differences between truck-mounted crane types—particularly the advantages of articulated knuckle boom cranes—can help you choose the right equipment partner for your project needs.

At Up! Up! Lifting, our International 4300 flatbed features a truck-mounted HIAB articulated knuckle boom crane that delivers exceptional versatility for the diverse material handling challenges we encounter throughout Asheville and Western North Carolina.

Understanding Truck-Mounted Crane Types

Truck-mounted cranes fall into two primary categories, each with distinct characteristics that make them suited for different applications:

Telescopic Boom Cranes (Straight Boom)

Telescopic boom cranes feature a straight boom that extends and retracts telescopically, similar to a telescope or radio antenna. The lifting mechanism relies primarily on a winch with wire rope to raise and lower loads. These cranes excel at:

- Maximum vertical reach – Can achieve working heights up to 200+ feet with jib extensions

- Long horizontal reach – Wire rope hooks extend working radius beyond boom length

- Precise vertical control – Wire rope and winch system provides smooth vertical lifting

- Heavy lifting at distance – Better capacity at extended horizontal distances

- Personnel lifting – Designed to accommodate work platforms for elevated access

- Load suspension – Can hold heavy loads suspended at height for extended periods

Best applications: Utility work, telecommunications infrastructure, high-rise construction, oil and gas operations, and any application requiring maximum vertical reach or extended load suspension.

Articulated Knuckle Boom Cranes

Knuckle boom cranes feature multiple articulated joints (or “knuckles”) that allow the boom to fold and bend like a human finger or robotic arm. Also known as picker cranes, loader cranes, or articulating cranes, these cranes use hydraulic cylinders rather than wire rope for most lifting operations. Their advantages include:

- Compact storage – Folds up behind the truck cab, maximizing cargo bed space

- Tight space maneuverability – Articulated joints navigate around obstacles and into confined areas

- Horizontal lifting capability – Lifts loads horizontally with minimal vertical clearance required

- Multiple attachment options – Can be fitted with pallet forks, grapples, buckets, augers, and specialized tools

- Lightweight design – Leaves more payload capacity available for hauling cargo

- Quick setup – Minimal space needed to position and operate compared to traditional cranes

- Precision placement – Multi-axis movement allows pinpoint accuracy when positioning loads

Best applications: Construction material delivery, landscaping, manufacturing, warehousing, marine operations, forestry, and any situation requiring frequent loading/unloading in variable or restricted environments.

The Knuckle Boom Advantage: Why Articulated Cranes Excel

While telescopic boom cranes dominate certain specialized applications, knuckle boom cranes offer significant advantages for the material handling, delivery, and placement operations that most contractors, builders, and businesses require.

1. Exceptional Maneuverability in Tight Spaces

The articulated design of knuckle boom cranes provides unmatched flexibility in confined working environments. The “knuckles” allow for articulation, a bendable action much like the way knuckles move on human fingers, enabling the crane to reach around obstacles, work close to buildings, and operate in spaces where telescopic cranes simply cannot function.

This makes knuckle boom cranes ideal for:

- Urban job sites with limited space

- Residential properties with narrow access

- Warehouse and factory environments with overhead obstructions

- Mountain properties with trees and terrain obstacles

- Rooftop deliveries without interior building access

2. Compact Design Maximizes Payload Capacity

Lighter than conventional boom cranes, the articulated boom is mounted on a truck, which takes up minimal space. This leaves room to carry additional payload on the truck bed as well.

When the crane folds compactly behind the cab during transport, more space remains available for cargo. Our 16-foot flatbed can carry up to 12,000 lbs of materials while still providing full crane capability—an efficiency that telescopic boom trucks cannot match since their boom structure typically stows over the cargo bed.

3. Versatile Attachment Capabilities

Much like a robotic arm, the knuckle boom can be fitted with various “hands” at its end, such as aerial work baskets, grabs, clamps, pallet forks, breakers, and augers, dramatically expanding the range of tasks a single crane truck can perform.

This versatility means one vehicle can:

- Lift palletized building materials with fork attachments

- Handle loose materials with grapple attachments

- Place precision items with standard hooks

- Drill post holes with auger attachments

- Manipulate awkwardly shaped cargo with custom fixtures

4. Horizontal Lifting and Low Clearance Operation

Unlike telescopic cranes that primarily lift vertically, knuckle boom cranes excel at horizontal lifting and can work effectively in low-clearance situations. The articulating loader crane allows the operator to load or unload the cargo with much less vertical clearance required compared to a straight boom crane.

This capability is crucial for:

- Loading and unloading in warehouses with height restrictions

- Working beneath power lines or tree canopies

- Placing materials through doorways or windows

- Accessing properties with overhead obstructions

5. Faster Setup and Operation

Unlike traditional cranes, which require assembly and disassembly on site, knuckle boom trucks can be driven directly to the job site and set up quickly and efficiently. The compact footprint means less space is needed to stabilize and operate the crane, reducing setup time and allowing work to begin immediately upon arrival.

For contractors and businesses making multiple stops throughout the day, this efficiency translates directly to productivity and cost savings.

6. Superior Operator Safety and Visibility

Many knuckle boom cranes offer remote control operation, allowing operators to position themselves for optimal visibility and safety. With traditional cranes, workers must climb up and down the crane to operate it, which can be dangerous and time-consuming. Knuckle boom trucks are operated from the safety of the cab, reducing the risk of accidents and injuries.

Up! Up! Lifting’s Knuckle Boom Specifications

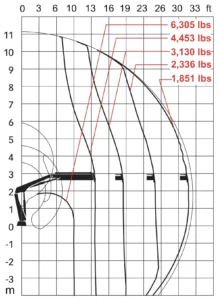

Our truck-mounted HIAB articulated knuckle boom crane delivers professional-grade lifting capability with the flexibility Western North Carolina projects demand:

Maximum Reach: 31 feet with telescoping extension boom

Lifting Capacity at Various Distances:

- At 9.9 feet: 6,305 lbs

- At 13.7 feet: 4,453 lbs

- At 19 feet: 3,130 lbs

- At 24.9 feet: 2,336 lbs

- At 31.6 feet: 1,851 lbs

- Throughout full 31-foot reach: 1,800 lbs minimum capacity

Flatbed Capacity: 16-foot bed with 11,000 lbs payload capacity

This combination of reach and capacity allows us to handle the vast majority of material handling tasks that contractors, landscapers, building suppliers, and businesses encounter—from placing HVAC units on second-floor installations to delivering palletized materials to tight residential job sites.

Important Considerations When Using Crane Trucks

While crane trucks offer tremendous advantages, understanding their capabilities and limitations ensures safe, effective operations and realistic project planning.

Lifting Capacity Considerations

Distance Matters: All cranes lose lifting capacity as reach increases. Our crane lifts over 6,000 lbs close to the truck but reduces to approximately 1,800 lbs at full 31-foot extension. Always plan lifts based on the actual working radius required.

Load Weight Accuracy: Knowing the precise weight of materials is essential. Overloading creates safety hazards and can damage equipment. When in doubt, weigh loads before lifting.

Dynamic Loading: Swinging or moving loads create additional forces. Factor in a safety margin beyond static weight calculations.

Terrain and Space Limitations

Stable Ground Required: While our crane can operate on slopes that would challenge larger equipment, a reasonably level and stable surface is essential. Soft ground, excessive slopes, or unstable surfaces may require outrigger pads or alternative positioning.

Overhead Clearances: While knuckle booms excel in low-clearance situations, power lines, tree branches, and building overhangs must be evaluated before operations begin.

Access Routes: The crane truck must physically reach the work area. Steep mountain driveways, tight turns, narrow gates, and weight-restricted bridges all require assessment during planning.

Working Radius: The 31-foot maximum reach defines the furthest distance we can place materials from where the truck is positioned. Obstacles between the truck and placement point may require creative positioning or multiple setups.

Cargo Types: Ideal Applications

Knuckle boom crane trucks excel with:

Heavy, Compact Items:

- HVAC units and mechanical equipment

- Steel beams and structural materials

- Precast concrete products

- Palletized building materials

- Bundled lumber and roofing materials (bunks of lumber)

- Large landscape boulders and hardscape materials

- Equipment and machinery

- Bundled piping and ductwork

- Dumpster bags

Awkward or Bulky Loads:

- Box truck beds and vehicle components

- Hot tubs and spa equipment

- Large appliances

- Storage sheds and outbuildings (within weight limits)

- Industrial equipment and machinery

Palletized Materials:

- Standard 48″x40″ pallets of brick, stone, or block

- Bagged materials (concrete, gravel, mulch)

- Boxed goods and supplies

- Equipment rental deliveries

Cargo Types: Not Ideal for Crane Trucks

Some materials and situations are better served by alternative equipment:

Extremely Long Materials: Items significantly longer than our 16-foot flatbed (like 40-foot steel beams or long span trusses) may require specialized trailers or multiple-vehicle coordination.

Loose, Unsecured Loads: Materials that can’t be safely rigged, palletized, or containerized create safety hazards. Loose gravel, sand, or soil should be transported in dump trucks or containers.

Very Light, Bulky Items: Materials where volume rather than weight is the limiting factor (like large quantities of fiberglass insulation) may not justify crane truck services versus standard delivery.

Fragile Items Requiring Extreme Care: While our operators are highly skilled, items requiring white-glove handling or climate-controlled transport may need specialized services.

Suspended Load Requirements: Projects requiring loads to be held suspended at height for extended periods are better served by telescopic boom cranes with winch systems designed for that purpose.

Extreme Distance Requirements: Placements beyond 31 feet from where the truck can position, or lifts requiring 100+ feet of vertical reach, exceed knuckle boom capabilities and require larger mobile cranes.

Making Crane Truck Services Work for Your Projects

Understanding these capabilities and limitations allows for effective project planning and realistic expectations. When we discuss your project, we’ll assess:

- Material specifications – Weight, dimensions, and rigging points

- Site conditions – Access routes, positioning space, ground stability

- Placement requirements – Distance, height, obstacles, precision needs

- Timing and scheduling – Coordination with crews, weather, traffic

This collaborative approach ensures we arrive prepared with the right equipment, rigging, and plan to complete your lift safely and efficiently.

The All-in-One Advantage

The fundamental benefit of crane truck services lies in combining transport and lifting in a single, integrated operation. Rather than coordinating separate delivery and rigging services, you get:

- One vehicle to schedule and coordinate

- One operator with complete visibility of the entire operation

- One service call instead of multiple vendor appointments

- Efficient turnaround from pickup to placement

- Reduced costs compared to separate hauling and crane rental

For contractors managing tight schedules, businesses coordinating deliveries, and property owners tackling challenging projects throughout Asheville and Western North Carolina, this integrated approach delivers both convenience and cost-effectiveness.

Experience the Knuckle Boom Advantage

While telescopic boom cranes excel in specific industrial and utility applications, the versatility, maneuverability, and efficiency of articulated knuckle boom cranes make them the ideal choice for the vast majority of construction, landscaping, delivery, and material handling projects throughout our region.

At Up! Up! Lifting, we’ve chosen knuckle boom technology specifically because it solves the real-world challenges our customers face: tight mountain properties, urban job sites, residential access constraints, and the need for precise material placement combined with efficient transport.

Whether you’re a contractor coordinating material deliveries, a landscaper placing heavy hardscape elements, a building supply company serving customers without forklift access, or a property owner tackling a challenging project, our knuckle boom crane truck provides the capabilities you need with the flexibility Western North Carolina projects demand.

Ready to experience the crane truck advantage? Contact Up! Up! Lifting today to discuss your material handling needs. We’ll assess your specific requirements and provide a clear plan for safe, efficient lifting and transport throughout Asheville, Black Mountain, and all of Western North Carolina.

Let our articulated knuckle boom crane solve your toughest material handling challenges—combining precision, power, and versatility in one complete package.

Frequently Asked Questions About Crane Trucks

What is the difference between a knuckle boom crane and a telescopic boom crane?

A knuckle boom crane has multiple articulated joints that allow it to fold and bend like a finger, making it ideal for tight spaces and precision placement. A telescopic boom crane has a straight boom that extends and retracts, providing greater vertical reach but requiring more space to operate. Knuckle booms are better for material delivery and placement, while telescopic booms excel at high-altitude work and utility applications.

How much weight can a crane truck lift?

Lifting capacity varies by distance from the truck. Our knuckle boom crane lifts up to 6,305 lbs close to the truck (9.9 feet) and approximately 1,800 lbs at full 31-foot extension. All cranes lose capacity as reach increases, so the actual working distance determines maximum safe load weight.

What are the advantages of a knuckle boom crane?

Knuckle boom cranes offer compact storage, tight space maneuverability, horizontal lifting capability, multiple attachment options, faster setup than traditional cranes, and can work in low-clearance situations. They’re ideal for construction deliveries, landscaping, and material handling in confined or obstructed areas.

Can crane trucks work on residential properties?

Yes, crane trucks are excellent for residential properties. Their compact design allows access to tight driveways and narrow spaces where larger equipment cannot operate. The articulated boom can reach around obstacles like trees and buildings, making them ideal for mountain properties and established neighborhoods.

What types of materials are best suited for crane truck delivery?

Crane trucks excel with palletized building materials, HVAC equipment, steel beams, precast concrete, landscape boulders, bundled lumber, machinery, and any heavy compact items weighing up to 6,000 lbs (depending on placement distance). They’re ideal for items that need precision placement in challenging locations.

What can’t crane trucks handle effectively?

Crane trucks are not ideal for extremely long materials (over 16 feet), loose unsecured loads like bulk gravel or sand, items requiring loads suspended at height for extended periods, or lifts requiring more than 31 feet of reach or 100+ feet of vertical height. These situations require specialized equipment like dump trucks or large mobile cranes.

Do I need special permits for crane truck deliveries?

The crane truck operator handles equipment operation, but permits may be required for certain loads, road closures, or work in public rights-of-way. We coordinate necessary permits as part of our service. Property owners should verify any HOA or local restrictions before scheduling deliveries.

How much space does a crane truck need to operate?

Knuckle boom crane trucks require significantly less space than traditional cranes. Our truck needs enough room to position safely with stable ground, plus clearance for the boom’s working radius (up to 31 feet). We can often operate in spaces as narrow as a residential driveway, depending on specific site conditions.

Can crane trucks place materials on second floors or rooftops?

Yes, this is one of the key advantages of crane trucks. Our 31-foot reach allows us to place materials on second-floor decks, balconies, and accessible rooftops without requiring interior building access. This capability is ideal for remodeling projects and construction where ground-level access isn’t available.

How do I know if my project needs a crane truck or a different type of crane?

Consider the weight, distance, and placement requirements. If you need materials transported and placed within 31 feet of where a truck can park, with loads under 6,000 lbs (at close range) or 1,800 lbs (at full extension), a crane truck is ideal. For extreme heights (100+ feet), very long reaches, or suspended load requirements, larger mobile cranes are better suited. Contact us for a consultation—we’ll honestly assess whether our equipment fits your needs or recommend alternatives if necessary.